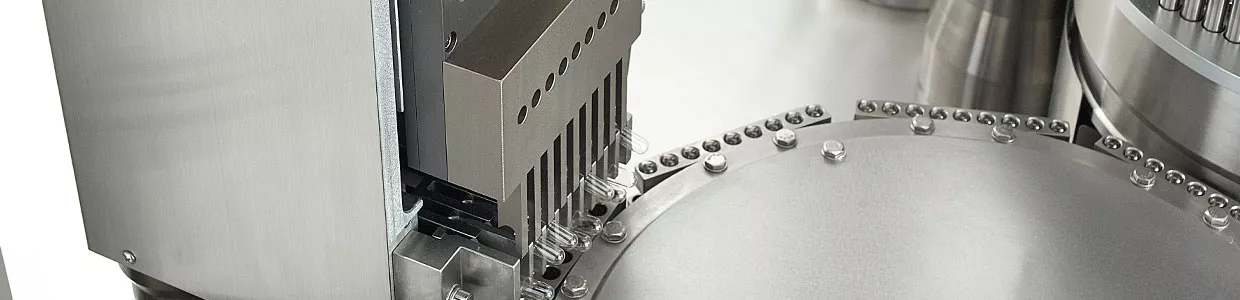

FACF Automatic Capsule Filling Machine

24,000 to 228,000 Capsule per Hour - The FACF is fully automatic to reduce labour costs and increase profitability.

#000 - #5 and Supro/safety capsule sizes A-E - The FACF is flexible in what size capsules it can produce. If you need to be able to produce a variation of capsule sizes, we sell additional tooling.

Lifetime support and training - Get in touch if you need to send a new member of staff to use for training. You can also contact us anytime and speak to an encapsulating expert.

The FACF range is for the manufacturer looking for exceptional output and efficiency while keeping batch profitability as high as possible with minimal downtime. The FACF range has been designed with all 3 of the above in mind so that the machine returns your investment as fast as possible by driving labour costs down and being extremely affordable.

Connect with Our Team

If you have a question or would like more details on the FACF Automatic Capsule Filling Machine, please complete the form below and someone from our team will be in touch with you soon.

The high filling rates of the FACF capsule fillers make them suitable for manufacturers in the pharmaceutical, veterinary, foodstuffs and chemical industries who require a low maintenance and large scale production capacity.

Main Benefits Of The FACF Range

- Easy to operate - With the LCD touch screen, the FACF range it’s very easy to operate with absolute accuracy. It’s very easy to adjust the filling weight, speed selection and capsule length adjustment on the display panel.

- Simple tuning process - We’ve created a video that shows you how to tune your FACF ready for production.

- Japanese made precision bearings for accurately dosed capsules - consistency is the key to a happy customer. This is ensured by the FACF’s advanced engineering which accuracy fills each capsule produced.

- Minimal downtime - The FACF has been designed for easy access for lubrication and cleaning. With a removable hopper, your production team be able to get to the parts you need to clean quickly reducing labour costs per batch.

- Spare parts - Like any machinery, something can always go wrong eventually. We stock spare parts and can ship them to you with next day delivery to keep downtime as low as possible.

- Capable of filling capsules with powder, granules or pellets - Whichever you feel is right for your product, the FACF can handle.

- Fills #00 - #5 and Supro/safety capsule sizes A-E - The FACF is flexible in what size capsules it can produce. If you need to be able to produce a variation of capsule sizes, we sell additional tooling here and have a step by step guide showing you how to change tooling here.

- Capsule Counting - Decide how many capsules you’d like to produce on the control panel and the FACF will take care of the rest. There is a live capsule counting option.

- Capsule rejection system - On the off chance that capsules are not to the FACF’s standards, they will be rejected into the powder slug rejection system.

Why Choose The FACF Range?

The FACF removes room for operator error by being fully automatic. This not only means the operator isn’t responsible for the output but also means the operator has very little to do when the machine is running. The fully automated filling process on the FACF range uses a vacuum capsule positioning system that ensures the capsules are placed and filled accurately. An operator could easily supervise several running FACFs because of the alarm system to warn the operator when powder is running low, yet again reducing labour costs.

It is the very simplicity of the FACF that stands out, along with the impressive rate at which they are able to fill capsules. You can simply churn out regular batches of perfectly filled capsules, each with a consistent dose of your chosen raw material. The consistency the FACF brings to your business makes purchasing the right amounts of raw materials streamlined because you’ll know exactly what output you’ll get out of it every time.

Warranty

The FACF range comes with a 12-month warranty on all parts including tooling. After your purchase, you will be emailed your warranty number which you will need to reference in the case of contacting us regarding any problems with the FACF.

Download The FACF Manual & Specification Sheet

Enter your details to get the User manual, Spec Sheet and Video links for the FACF Automatic Capsule Filler

How Much Training Is Required To Operate The FACF?

While we offer 1-day training at LFA facilities, we do require at least 2 days of training from one of our technicians at your facility so we can tune the machine specifically to your product. These 2-days with our technician will specifically be for training purposes, but if you need installation help, please let us know. Before shipping the machine to your facilities, our sales team will set up a time to have our technician meet you and the machine at your location. Our technician will spend 2 days with you and your team. During this time they will set up and install the machine and then walk you and your team through the ins-and-out of the machine. At the end of the 2 day training, if you feel you need more time with our technician we would be happy to extend the time for you.

Shipping

Click the “get a quote” button above and we’ll send you a quote for the total costs to get the FACF to your location. The price listed above is inclusive of VAT, but we’ll need to get a shipping quote from one of our trusted carriers.

We typically keep the FACF range in stock in our UK, US and Taiwan offices which means we’re able to ship them to just about anywhere in 3-5 working days. However, it’s worth getting in touch with to make sure there is one in stock in your local office.

Cleaning

The removable powder hopper makes gives easy access for cleaning and lubrication to make servicing much easier and reducing downtime.

Safety

The FACF has fully enclosed dosing stations for operator safety and to avoid cross-contamination. It also maintains the hygiene levels essential to working with food, pharmaceutical, industrial, medical or any other purpose including minerals or food supplements.

GMP & CE

To protect you and your business, all FACF contact parts are made from fully GMP conforming stainless steel. The FACF electronics are also fully CE approved.

Technical Specifications

| Specification | FACF 400 | FACF 1200 | FACF 2000 | FACF 3500 |

|---|---|---|---|---|

| Maximum Capsules/Minute | 400 | 1200 | 2000 | 3500 |

| Capsule Sizes Compatibility | 00 / 00E / 0 / 0E / 1 / 2 / 3 / 4 / 5 | |||

|

Filling Precision |

±3% | |||

| Filling Bores | 3 | 9 | 18 (Double Row) | 24 (Double Row) |

| Decibels (db) | ≤70 | ≤78 | ||

| Gross Weight | 840kg / 1,851lbs | 855kg / 1,884 lbs | 1,805kg / 3,979lbs | 1,805kg / 3,979lbs |

| Net Weight | 735kg / 1,620lbs | 745kg / 1,642lbs | 1,600kg / 3,527lbs | 1,600kg / 3,527lbs |

|

Power US |

220v, 3 phase Wye (Y), 3.75kW, 60Hz | 220v, 3 phase Wye (Y), 3.75kW, 60Hz | 220v, 3 phase Wye (Y), 6.82kW, 60Hz | 220v, 3 phase Wye (Y), 6.82kW, 60Hz |

|

Power UK |

440v, 3 phase Wye (Y), 3.75kW, 50Hz | 440v, 3 phase Wye (Y), 3.75kW, 50Hz | 440v, 3 phase Wye (Y), 6.82kW, 50Hz | 440v, 3 phase Wye (Y), 6.82kW, 50Hz |

Dimensions of the FACF Range

| Dimension | FACF 400 | FACF 1200 | FACF 2000 | FACF 3500 |

|---|---|---|---|---|

| Length | 800mm / 31.5in | 1,410mm / 55.5in | ||

| Width | 970mm / 38.1in | 1,280mm / 50.4in | ||

| Height | 1,870mm / 73.6in | 2,000mm / 78.7in | ||

Output per Machine and Capsule Size

| Machine Model | Capsule Size | Maximum Output/minute* |

|---|---|---|

| FACF 400 | #000, #00, #00E, #0E | 360 |

| FACF 400 | #000, #0, #1, #2, #3, #4, #5 | 400 |

| FACF 1200 | #000, #00, #00E, #0E | 1,100 |

| FACF 1200 | #000, #0, #1, #2, #3, #4, #5 | 1,200 |

| FACF 2000 | #000, #00, #00E, #0E | 1,800 |

| FACF 2000 | #000, #0, #1, #2, #3, #4, #5 | 2,000 |

| FACF 3500 | #000, #00, #00E, #0E | 3,000 |

| FACF 3500 | #000, #0, #1, #2, #3, #4, #5 | 3,500 |

How Much Profit Will This Machine Generate?

Are you able to calculate the amount of profit your business generates per capsule? If so, this calculator will be able to tell you how many hours you will have to run this capsule filler to cover its investment.

It will also be able to tell you the amount of profit it will generate every hour you run this capsule filler, which makes this calculator a powerful tool when deciding on which capsule filler is right for you or your business.

Profit Generated Per Hour

This machine returns it's investment in hours

All of them. There are 10 capsule sizes 000, 00E, 00, 0E, 0, 1, 2, 3, 4, 5 the SACF 25 Semi-Automatic Capsule Filler or FACF Automatic Capsule Filler can be made to fit any of them with a tooling change.

The machines that we hold in stock are usually size 00 or 0.

The FACF rage comes with one set of tooling.

We typically hold size 0 and 00 in stock as these are the most popular.

If the customer would like another size then this is definitely possible. They will, however, need to be ordered and fit into a machine we have in stock or a new machine with the correct size will have to be built.

Yes, it is called a capsule polisher and most customers that buy a capsule filler will also want to buy one of these.

You can find them for sale on our website here:

Yes, the FACF has a count function. You are not able to tell the machine to automatically stop at a set count but you are able to tell how many capsules you have produced so far.

Just as with a tablet press or any other piece of equipment is best to start at the top and work your way down. First, do a dry clean, then clean with cleaning products, then sanitise and then make sure it is dried and oiled.

The product that a customer would want to use would depend on the industry that they are in. Most customers of the FACF will be in the food or supplements business. Because of this, they will want to make sure that all of the products that they use are food safe.

All of them, we are able to build it to take from size 000-5 a full chart of the sizes can be found here: https://www.lfacapsulefillers.com/capsule-size-chart

It is in principle fairly easy and takes about 3 hours.

Here is a video tutorial on changing tooling: https://www.lfacapsulefillers.com/videos/facf-capsule-filler-tooling-change

Yes, the capsules that the FACF takes are what are called “two piece capsules” or “whole capsules” you can get separated capsules where the tops and the bottoms come separately but this is a different product.

No. You have to use capsules that come in one piece. It is also important to remember that you can not recycle a capsule through the machine. Each capsule can only be used one. Even if it is not filled.

The tolerance of the capsules are very small and once they have been through the machine once the chance of them getting stuck of causing a jam dramatically increases.

No, is the simple answer. Liquid filled capsules are of a different type of construction.

The soft gels like the omega oil products are made on a different machine.

Yes, the FACF uses software called WinCC. This is open source and the customer is free to make any changes they like.

We would recommend that they have a copy of our software available first so that if any changes they make do not work with the machine then they can reinstall the original drivers.

The machine should really have someone to watch over it. It is less intense work than a tablet press but in the event that something does jam you will want to catch it quickly.

The main problem is that issues build up fast. If one capsule hole gets blocked then every cycle will through an extra capsule into the operations of the machine. This can Block other holes and increase the issue. Eventually, you can be left with quite a mess. It is better to catch this early.

It takes 1 day for LFA to train your production team.

This includes an in-depth dive into the machine showing a tooling change, clean down, tuning, greasing and talking them through all of the mechanics.

Raw ingredients will work it is one of the major benefits to the customer of a capsule filler. It is able to handle products that are sticky, damp or granular.

Some products can still have issues with powder flow. If your product is one of these then flowing agents and anti-caking agents like Firmafill may prove helpful.

As with all things, it will depend on the product. As you can see from the question above you might not need to use binders and flowing agents. However, if your product has flowing issues or if you would like to get it to perform in a set way then yes you may need to formulate your capsule.

The most important thing will be something called tamping. This is working out how much powder can be pushed down into the capsule. For this LFA will be offering formulation services.

No, the FACF does not require an air compressor.

The main unit of the machine is not noisy. There is however a vacuum unit that is quite noisy. We would recommend installing this outside of the main room which the capsule filler is installed in.

The other item that comes with the FACF is with the vacuum cleaning unit.

This is quite noisy and needs to be close to the machine. We would recommend that people using the machine for long periods of time ware PPE including ear protection.

The FACF can be operated safely with just one person.

If LFA was setting up an operating procedure for the FACF it would recommend that if the machine is operated by 1 person then the area would be monitored or they would have a way of contacting help if required.

No. Most capsules are made of one of two products, gelatine or HVAC (vegetarian) as long as the capsules that the customer wishes to use are of the size of the tooling that they have then there will be no issue with them working in the machine.

Yes, it can, as long as they are one of the standard sizes that the machine takes.

Time release capsules are not dependent on the machine but instead require the user to use special capsules that are acid resistant.

Yes, but the minimum order is 10,000,000 and will cost about USD $0.005-0.03 per cap. Depending on the colour, material and if they want it printed.

We are able to offer, different color capsules in various sizes, we are even able to print a logo right onto the capsule.

If this is something that you are interested in then get in touch.

There are two hoppers on the FACF. The first is the capsule hopper, this can hold around 5000 - 00 capsules. The second hopper holds the powder, the amount of powder that it can hold will depend on the bulk density of the product but a good estimate is 5-10kgs.

We would recommend at least 1m (3.5ft) in every direction around the machine. This would be cramped but would give the operator enough space to run the machine and clean and service it.

The minimum amount of raw ingredient for a FACF would be around 1kg on the FACF 200 building up to about 5kgs on the FACF 3800. This would depend on the flow qualities of the powder.

It takes approximately 4 hours to do a full clean down of a FACF, regardless of its size. To do a full clean down you should start with removing all of the tooling. At this point, you will be able to properly clean down the machine.

You will then have to lubricate the machine and reassemble it. Because of this, it does not take much less time to do a smaller model compared with a larger one.

Yes, there are two sections of the FACF that could need tuning depending on the state the machine was last left in.

The first section is the capsule sowing. If the tooling has been taken out to be cleaned then this will need tuning. To do so can take 1-2 hours.

There have been times when we have done it in 10-20 mins but it was luck.

The problem is that the tolerances on the capsules are so tight something can be off by 0.02mm and capsules will go everywhere. This can take time to get into the correct position.

The second part that needs tuning is the powder flow section. This will take around 30 mins to 1 hour and will need to be done every time that the capsule filler has a new product put into it.

If you are changing from one herb say to another and your SOPP does not require a full clean down then it will take 30 mins to just tune up for the next batch. This should only be done when small amounts of one product getting into the next would not cause a major health risk or product quality issue.

If they are not able to go from one product to another without a full clean down then it will take around 4 hours.

It will depend on the skill of the operator and the size of the FACF. The FACF 1200 takes about 3-4 hours to do a full tooling change from one size of capsules to another.

The tooling on the FACF should be cleaned down every time a run is finished. It is really bad for the machine to be left dirty, especially if the customers' products are sticky, hygroscopic, acidic or corrosive in any other way.

I would say that the FACF is not suitable for R&D it is too big, too expensive and requires too much product to be effective as an R&D machine. On top of that capsules unlike tablets do not experience a big change in process from a SACF to a FACF.

Yes, if specifically requested we could set up one of the smaller FACF’s for single phase however this is not recommended as the power consumption would be very high.

Yes, each of the FACF capsule fillers comes with a 12 month warranty on all of the parts, including tooling. This is slightly different to other machines for which the warranty often does not cover the tooling.

The estimated life of the FACF range is 10+ years when maintained correctly. During this time there are going to be a number of key components that will need changing to ensure that this is possible.

- The bearings that control the tooling on the main turret.

- All of the gaskets.

- The tooling.

These are some of the main wear parts, but as they are fairly affordable to replace there is no reason not to.

No, the machine does not come fully assembled. There are a number of steps that need to be taken when you first receive your FACF. Here is a short list:

- Attach Auger Filler

- Attach Powder Hopper

- Wire plug to the extension cable

- Fit Capsule Hopper extension

- Connect Vacuum Unit

- Connect Suction Unit

If you would prefer for this to be done by LFA we are more than happy to provide an installation team. This, however, would have to be quoted separately, More information can be found on that here: https://www.lfacapsulefillers.com/services

Yes, all of LFA’s machine have user manuals. You can download it on the product page.

The long manual will be emailed to the customer in PDF format, along with all of the other technical documents once you have made your purchase.

Yes, this would be a great next step. Because of the way that the capsule filler works it will be able to overcome some of the problems tablet presses can face, especially: Friability issues, capping, not binding, laminating and flowing issues.

If in doubt, get in touch and we can test your product on one of our machines: https://www.lfacapsulefillers.com/contact/

The FACF is an extremely safe machine. It has perspex doors that stop the operator from being able to come into contact with any of the moving parts while the machine is in operation.

All of the doors have sensors so that if opened the machine will automatically stop. On top of this, the machine has an emergency push stop which can be used when the operator is working inside the machine.

Yes, as with all of our machines it comes with lifetime technical support. All the customer has to do is call up with their warranty number and we can start to assist them.

If the customer would like us to come to them to fix the machine then this is also a service we are able to offer. This is a charged for service. Please contact us for more information.

At the moment we do not offer an App or Web App to be able to monitor or control the machines.

This being said the FACF is run on a software called WinCC, this software is open source. As well as this the FACF does have an ethernet cable point so can be connected to a network.

If you would like to try and set a link, we are happy to try and support you but it is not something that we have attempted before and you would have to bring most of the skills to do it.

Yes, we are happy to give onsite training. Normally this would be invoiced for separately. More information can be found on this here: https://www.lfacapsulefillers.com/services

Yes, the speed of the capsule filler can be adjusted. The maximum speed that can be selected will be the number of the machine (the FACF 200 will do 200 caps per min at the maximum speed well the FACF 3800 will do 3800).

This is all controlled via the touch screen.

Yes, it has a CE certificate, and it will be compliant with the ISO 22000 rules.

When it comes to GMP certification, it is important to remember that each government, country, state, governing body, qualification all have different rules.

If you want to be sure, you are able to come and inspect the machines ant any one of the tradeshows we attend or in one of our showrooms in the UK, US or Taiwan.

No, the tooling stays the same.

Yes, all of the FACF machines come with a vacuum that should be plugged in and run during the operation of the machine. This takes away excess powder and rejected capsules.

As well as this the FACF has fully inclosed perspex doors the contain any fine particles during operation.

There is not a capsule cleaning function built into the FACF. IT is a good practice for the capsules to be cleaned or polished after they have come out of the FACF.

To do this you will need to buy a capsule polisher. We do currently sell capsule polishers, they can be found here: https://www.lfacapsulefillers.com/cp-7000-capsule-polisher

Yes. You do this through a section of the machine called the tamping section. You are able to increase the tamping to compact the powders more this then increases the weight of the capsule. You can decrease the tamping to reduce the weight in the capsule.

There is a minimum and maximum weight that each powder will be able to achieve in any capsule size. This will depend on the bulk density of the powder, how directly compressible it is, and what size capsule is being used.

The tooling on a capsule filler is not like that on a tablet press. Because it does not get put under extream forces the life of the tooling is much, much, much longer. It will wear over time but this could be 5-10 years depending on usage.

This is as long as you are looking after the tooling. The worst thing you can do is overtighten the tamping section and cause a collision in the tooling. This will damage the tamping pins.

As long as you never do these two things the tooling will last a very long time.