Case Study: Increasing Capsule Production Speed with LFA Machines’ Empty Capsules

Executive Summary

A U.S.-based supplement manufacturer faced major capsule quality issues that slowed down production. Capsules were not separating properly in their fully automatic capsule filler, causing wasted material and rejected capsules. After switching to LFA Machines’ empty gelatin capsules, the company saw a marked improvement in performance and a 20% increase in production speed.

A U.S.-based supplement manufacturer faced major capsule quality issues that slowed down production. Capsules were not separating properly in their fully automatic capsule filler, causing wasted material and rejected capsules. After switching to LFA Machines’ empty gelatin capsules, the company saw a marked improvement in performance and a 20% increase in production speed.

About the Manufacturer

The company produces a range of encapsulated herbal and nutritional supplements for the fitness and wellness market. They needed a dependable, high-quality supply of capsules that would run smoothly in high-output automated equipment.

Challenges and Objectives

The manufacturer experienced problems with capsule halves sticking together during production. This prevented proper separation in their fully automatic capsule filler, which resulted in product loss and machine downtime. They required a reliable bulk supply of size #000 gelatin capsules that could maintain consistent quality and function efficiently during production.

The Solution

LFA Machines offers a wide selection of empty capsules, including both gelatin and vegetable-based types, across sizes #000 to #5. Their gelatin capsules are engineered with precise tolerances to ensure smooth operation in automatic filling machines. By switching to LFA’s capsules, the manufacturer eliminated the separation issue and improved production consistency.

The Results

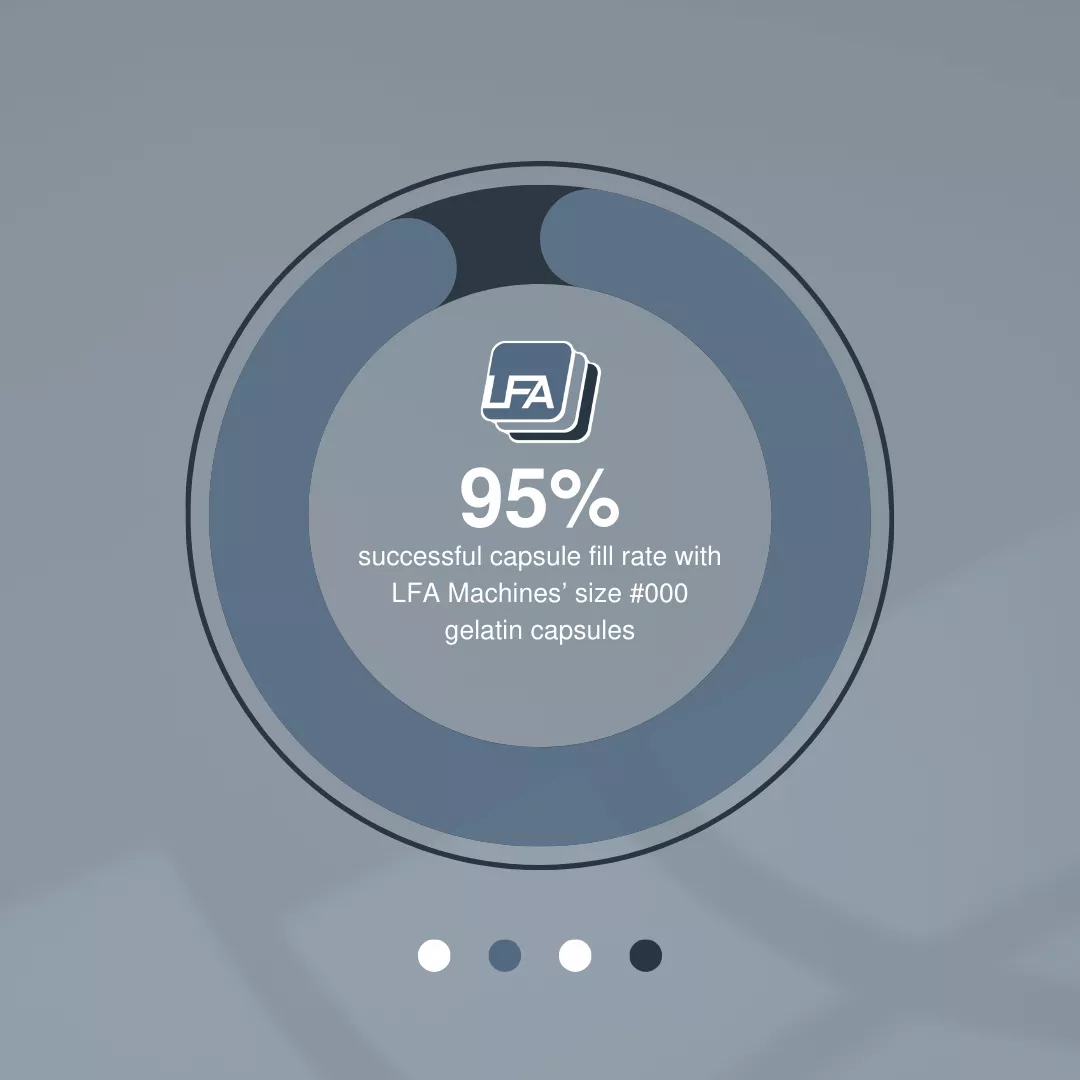

After adopting LFA Machines’ size #000 gelatin capsules, the company achieved a 95% successful fill rate and a 20% boost in production speed. Manufacturing downtime decreased significantly, and the production line ran more efficiently. The team also praised LFA Machines for their quick support and reliable product quality.

After adopting LFA Machines’ size #000 gelatin capsules, the company achieved a 95% successful fill rate and a 20% boost in production speed. Manufacturing downtime decreased significantly, and the production line ran more efficiently. The team also praised LFA Machines for their quick support and reliable product quality.

Continued Growth

With improved capsule performance and reduced downtime, the manufacturer has been able to scale production and support new product launches more efficiently.

Interested in High-Quality Capsules?

LFA Machines’ empty gelatin capsules are GMO-free and made from natural sources. They’re available in sizes #000–#5 and in quantities from 150 to 100,000. LFA also offers plant-based HPMC capsules and organic pullulan capsules made from tapioca extract.

Contact us today to learn more.